Earlier this year, US construction giant Trimble and its modelling software arm Tekla joined ResponsibleSteel. Here, Technical Manager Mick Hodgson explains what this means and where steel sits within a net zero future for the built environment industries.

It’s no secret that the carbon impact of construction is coming under even greater scrutiny. There’s plenty of shocking statistics around that demonstrate just how much of a problem we are facing, such as the fact that the built environment accounts for around 40% of global energy related CO2 emissions. Or that the manufacturing and disposal of materials used in structures accounts for approximately 11% of all greenhouse gases.

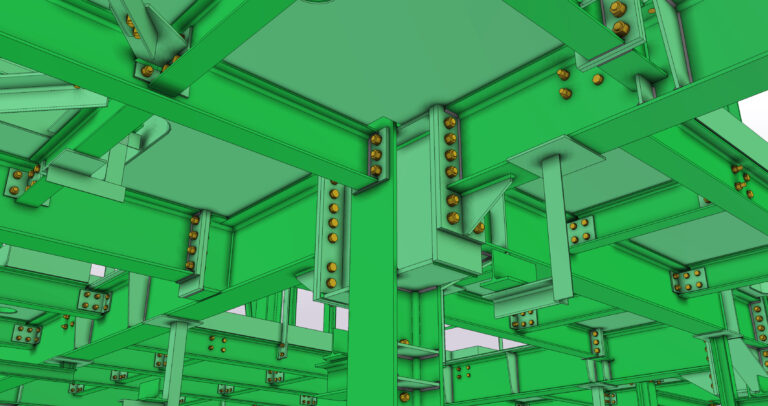

We are seeing an increasing number of new regulations and standards coming in around sustainability, all focused around using low carbon solutions. Companies and project teams are increasingly having to prove and document that they are doing all they can to reduce the structure’s carbon footprint, from details of where they sourced the steel, to what connections they’ll be using at the fabrication and assembly stage (i.e. welds versus bolts and other design or manufacturing considerations), to the optimisation of the structure’s steel frame.

Nor is it just governments and officials that are driving this change – client demand is also a key factor, with building owners and stakeholders wanting to know that their new development is the most green and sustainable it can be. While change has hit the industry fast, it’s great to see that companies are also wanting to do better and do their bit on the journey to net zero.

So, where does the steel industry fit within this? To me, I see steel as being one of the most progressive and forward-thinking industries in construction. I’ve worked within structural steel for my whole adult life, from joining a local structural steel fabricator at the age of 16, moving into the drawing office at 22 just as computerisation and software began to infiltrate into the industry, studying computer science at university, before then working within the BIM software field.

Today, the structural steel industry is really leading the way and setting the standards for automation, health and safety, efficiency, training and upskilling, and harmonising standards, with the rise of automated production lines, computer technologies, robotics and offsite processes. Now, we’re looking to work together towards a more sustainable and greener future for structural steel.

Industry organisations, such as AISC in America, BSCA and SCIA in the UK and CSA in China, are at the forefront of this change, helping with documentation, standards and advice. They are helping companies to understand the environmental implications of their chosen steel suppliers, structural designs and fabrication techniques, in addition to the value that automation and robotics can deliver. It doesn’t end there either, looking at carbon contributing factors like power, water supply, waste and transport, as well as what happens when the structure reaches the end of its life and is decommissioned.

ResponsibleSteel is one of the new industry organisations, marking the steel industry’s first global multi-stakeholder standard and certification initiative. ResponsibleSteel is defining a new set of global standards for steel, including quality assurance and carbon footprint certification. Supported by the rise of new green steel mills and new steel manufacturing techniques, imagine a piece of steel that has a zero-carbon footprint attached – this is the future we are looking at.

ResponsibleSteel currently has 138 members and represents a wide selection of steel suppliers and manufacturers, engineering consultancy firms (like Arup and Mace) and large to family-run fabrications – essentially a cross section of the entire supply chain. Nor is it limited to just construction, with representatives from the automotive and wind energy industries too. Trimble marks the first BIM software technology provider to be a member of ResponsibleSteel, with its Tekla constructible modelling software, taking an active role in helping to define the new industry standards.

As well as helping our Tekla software users to move forwards, being a member is a great way for us to both show our support of the industry and further educate members on the value of data rich models when it comes to creating EPDs and other carbon documentation. For me, it’s really all about encouraging change and helping deliver new standards across the board. Structural steel is a great example of a circular industry – a term that has become a real ‘buzz word’ over the last few years but also remains very apt.

Moving forwards, it’s about making greener and more considerate decisions at every stage of a project: from sourcing the raw steel in a responsible manner, reducing material waste, producing accurate quantity take-offs and only purchasing what you need, exploring welded versus bolted connections etc, designing greener, working hard to further optimise the structural steel and ensure it’s working hard, reusing and recycling materials where possible (such as on redevelopment or renovation projects), and even considering the transportation of materials from the steel mills to the supplier, fabricator, contractor and eventually to site.

It’s clear that organisations like ResponsibleSteel are going to be a big part of the steel industry going green and meeting the net zero targets. It goes beyond producing and delivering global standards and ensuring everyone is signing off the same hymn sheet, and is perhaps more about getting the big industry players together. While it is governing bodies who set the rules and regulations, it is the industry players who can influence the mindset of others and help spread this desire and need for change throughout the supply chain and on the ground.

source:https://environmentjournal.online/features-opinion/can-responsiblesteel-clean-up-construction-industry/